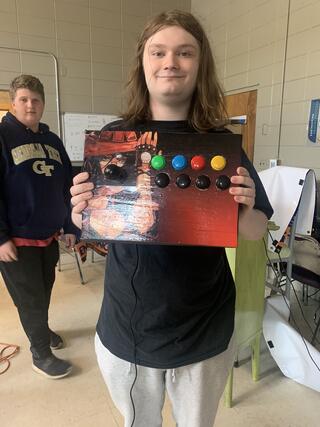

Matthew Fowler and Bryce Parrett

Wayne Weaver

Electro-Man, a gaming console, mechanical toy and a cartridge holder for Nintendo games are just a few of the products students created for a capstone project to exit Engineering I and II at Neshoba Central High School for the 2021-2022 school year.

Instructor Sedera Anderson said students had to either create something or solve a problem as part of the end-of-year assignment called a capstone project.

“The project had to serve a purpose,” she said. “It could be a sellable product or it could solve a problem.”

Students had to make their product utilizing four machines and their Solidworks software, which is their CAD drawing program.

“They had to have a Power Point just like they were trying to present and sell me their product,” Anderson said. “Boys had to dress in collared shirts and dress pants and girls in nice dress clothes.”

Their dress was part of their grade along with the Power Point presentation.

Anderson said the goal was for the engineering students to have improved their presentation and soft skills from the first time they walked into her lab at the beginning of school.

“When they come in the first time, they are really nervous about presenting in front of the students,” she said. “We have been presenting throughout the year and we critique each time.”

One thing Anderson preaches to her students is that a Power Point is a guide that is not to be read verbatim, it is a tool to guide them as they present.

“They are the ones who know their product, so they shouldn’t hesitate in trying to sell it to me,” she said. “They are graded on how they present to me. Professionalism is the key, from how they appear to how they present themselves. This is what soft skills are about.”

The second grade is the actual project.

“Of course, there needs to be a difference in how you enter the program with projects, how you exit the program with projects, and how you use the machines,” Anderson said. “The key is being able to be creative, as well as showing their capabilities on mastering the machines available.

“Sometimes they will 3D print their logo or create a logo and engrave it into something whether it’s their product or on just a piece of wood. A lot of them use the wood router or plasma cutter to cut out part of their project.”

The third grade from the project is their portfolio, which is like an engineering notebook. It had to have the engineer drawings they used on the Solidworks program.

“It had to have a log of the entire process of their capstone project,” Anderson said. “It had to be professional. It should be detailed as well. I should be able to take their portfolio and recreate the project just from the contents of this book. It is a major part of the grade. Again, it is about professionalism.”

Students could do their projects individually or in groups of two.

Students Wayne Weaver and Gracie Waldrup worked together to produce a gaming console. It included buttons and game controls.

“It would sell for $150 to $200 if you bought online,” Anderson said of the project. “It can be hooked up to any game that takes joy sticks and controls.”

Student Ethan Coghlan created a mechanical cartoon-like claw.

Jordan Turk created a water bottle holder for his treadmill while Jaxon Dunaway and Grant Sullivan created a Nintendo game cartridge holder.

Their business was J&G Gaming Accessories.

Madison Eickoff used epoxy and stump pieces and created cup holders with small Resin printed items hidden in the epoxy.

Engineering I student T. J. Phillips showcased a camping set with a plastic fork, spoon and knife.

“He used a 3D printer and hooked it together,” Anderson said. “It’s a small set that would fit in your pocket.”

Isiah Beckham showcased his Electro-Man, utilizing the 3D printer. There were electrical wires and LED lights, which were hooked up to a battery.

Overall, Anderson was very pleased with the improvements shown by her engineering students.

- Story by Debbie Burt Myers